The Sarawak Premier announced that the Bintulu-Samalaju road will be resurfaced using new technology that incorporates plastic waste.

This was said during the Gabungan Jurutera Perunding Bumiputera Sarawak (GJPBS) anniversary dinner on 17th June 2023.

As Sarawak is mulling with the idea of using plastic waste to build, could this be the solution to manage the issue of plastic waste here?

Malaysia is now actively carrying out studies on the use of plastic waste as a component, along with asphalt, for resurfacing roads.

One of the main reasons is that the conventional asphalt road has shorter lifespan and has higher road maintenance cost.

In 2021, Malaysia imported more than 500 thousand tons of plastic waste and exported around 11 thousand tons, making the country one of the major importers of plastic waste globally.

Some of the top countries that sent their plastic waste to Malaysia include the U.S. and the countries of the European Union.

Therefore, it can be said that making roads using plastic in Malaysia is a great idea.

On a global scale, the use of asphalt and plastic waste was not exactly a new technology as it had been used by India for the last 15 years, as India has used plastic waste as a component to pave about 25,000km of road.

At present, this technology is growing in Britain, Europe, and Asia.

Several countries — South Africa, Vietnam, Mexico, the Philippines, and the United States, among them — have built their first plastic roads only recently.

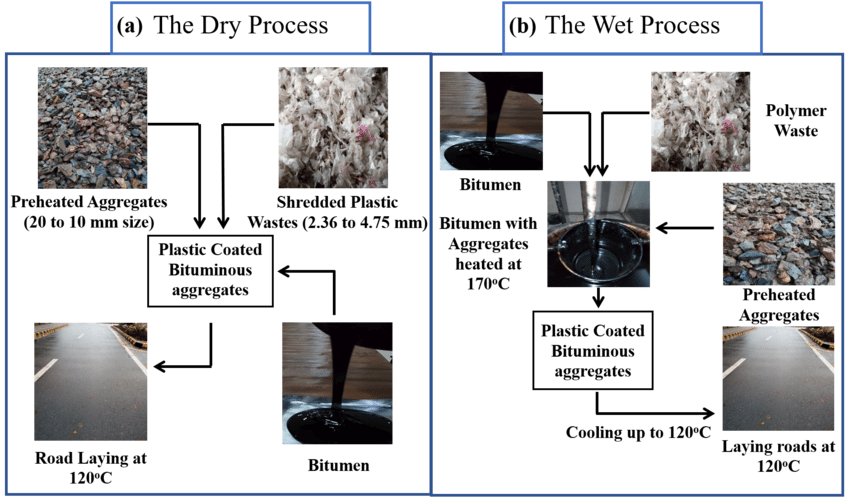

Researchers have investigated the practicality of using recycled plastic in the construction of roads.

The Public Works Department’s Centre of Excellence for Engineering and Technology (CREaTE) is currently testing road pavement technology utilising waste plastic asphalt, as well as latex asphalt, at two sites: the FT98 federal road in Kerdau, Temerloh, Pahang; and FT3 federal road in Chukai, Kemaman, Terengganu.

At the Temerloh site, a 645-m stretch of road (one lane) was paved with latex asphalt (a mixture of natural rubber latex and asphalt). The road paving works on both stretches were completed in September 2017.

At the Kemaman site, CREaTE is testing three types of paving materials, namely, waste plastic asphalt over one lane of a 615-m stretch of road; latex asphalt over a 990-m stretch; and latex mastic asphalt over a 1,330-m stretch.

The study in Temerloh shows that the plastic waste road pavement does not show any pavement surface cracking after one year, while the conventional pavement cracked, six months after opening to traffic.

Adding to this, there are a growing number of studies that indicated that roads containing waste plastic have the potential to perform as well or better than traditional roads.

It is said that they can last longer, are stronger and more durable in respect to loads and rutting, can tolerate wide temperature swings, and are more resistant to water damage, cracking, and potholes.

Thus, this shows that plastic waste has a promising potential in the construction of roads.

The use of plastic waste to construct roads also has the potential to resolve any number of plastics from landfills and random dumping ground while at the same time providing solution for road paving and repair.

While most parts of the world are yet to use this technology, it can be seen as one of many strategies for a circular economy in Sarawak.